Tankless water heaters are marketed as efficient, low-maintenance systems. When they operate properly, they deliver steady hot water without the footprint of a storage tank. When they fail, the shift is usually abrupt — cold water mid-shower, fluctuating temperatures, or an unfamiliar error code flashing on the display.

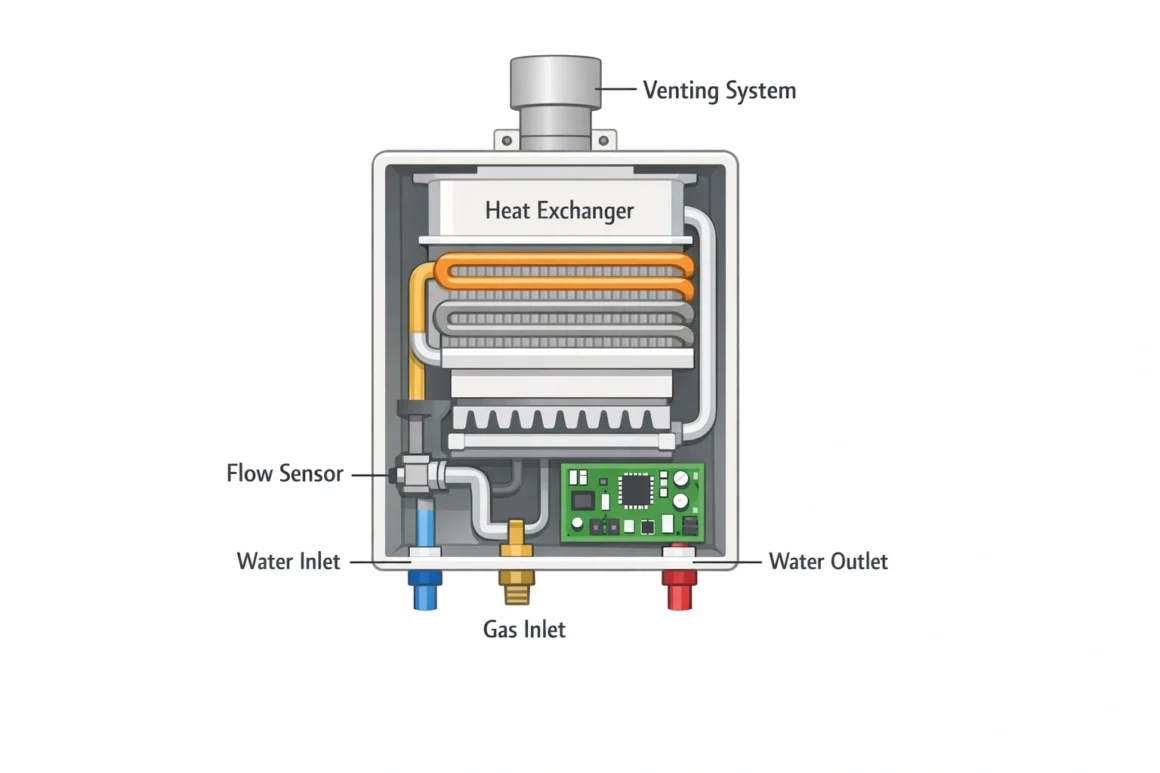

Unlike traditional tank units, tankless systems depend on sensors, flow regulation, gas or electrical components, and precisely configured venting. That complexity changes what “repair” realistically involves. Some interruptions trace back to routine maintenance or minor environmental factors. In other cases, the issue points to conditions that require licensed service to avoid gas leaks, electrical hazards, or carbon monoxide exposure.

Understanding how these systems behave under stress makes it easier to separate routine troubleshooting from situations that demand professional attention.

How Tankless Water Heaters Typically Fail

Tankless systems fail differently from traditional storage tank heaters. There is no reservoir to empty or leak. Instead, most problems emerge from components that regulate flow, ignition, temperature sensing, or venting. Because these units respond instantly to demand, even small disruptions can interrupt performance.

Scale buildup is one of the most common causes of reduced efficiency. In areas with hard water, mineral deposits accumulate inside the heat exchanger over time. This restricts heat transfer, increases internal stress, and may trigger error codes related to overheating or flow restriction. Without periodic flushing, performance gradually declines rather than failing all at once.

Flow sensor irregularities present differently. Tankless heaters activate only when sufficient water flow is detected. If sediment, debris, or sensor wear interferes with detection, the system may fail to ignite or may shut off unexpectedly during use. The problem usually feels inconsistent, not catastrophic.

Ignition issues are more abrupt. Gas-powered units rely on precise combustion conditions. If the ignition system, gas supply pressure, or ventilation pathway is compromised, the heater may display an error code and lock out operation. These faults are designed to prevent unsafe combustion rather than to allow continued partial performance.

Venting and exhaust obstructions can also trigger shutdown. Because tankless heaters operate with sealed combustion systems, airflow must remain within manufacturer specifications. Blocked or improperly configured venting can cause the system to stop functioning entirely as a protective measure.

What Homeowners Can Safely Check

Not every shutdown requires immediate service, but the scope of safe homeowner inspection is narrower than many online tutorials suggest. Tankless units are compact and component-dense. Opening panels or adjusting internal connections without training can create more risk than resolution.

Start with simple observation before assuming mechanical failure. Confirm that the unit has power, that no breakers have tripped, and that the display panel is active. Review the error code shown on the screen and compare it with the manufacturer’s documentation rather than relying on generic online advice. Many shutdowns are protective responses rather than mechanical failure.

Water flow is another non-invasive factor to evaluate. Tankless systems require a minimum flow rate to activate. If multiple fixtures are partially open or if aerators are restricted by sediment, the heater may cycle on and off unexpectedly. Ensuring consistent, adequate flow can resolve symptoms that appear more serious than they are.

Visible external conditions also matter. Check that intake and exhaust terminations are clear of debris, snow, or nesting material. Obstructions outside the unit can disrupt airflow without any internal component failure. This inspection should be visual only; vent components themselves should not be dismantled.

If the system has not been flushed according to the manufacturer’s maintenance schedule, scale accumulation may be contributing to reduced performance. In many cases, professional descaling restores efficiency without requiring component replacement.

Plumbing systems influence more than temperature and flow. Perception of cleanliness and reliability can also shape homeowner decisions, particularly when evaluating dark-colored bathroom fixtures in daily use.

When Professional Service Is Necessary

Some symptoms mark a clear boundary between homeowner checks and professional service. Tankless water heaters operate with high-temperature combustion or high-voltage electrical components. Attempting internal repairs without proper training can create safety hazards that are not immediately visible.

Persistent ignition failures, repeated system lockouts, or error codes related to combustion and gas supply should be evaluated by a licensed technician. These systems are designed to shut down when unsafe operating conditions are detected. Repeatedly resetting the unit without identifying the cause rarely resolves the problem.

Signs of gas odor, unusual exhaust smell, or visible corrosion around venting components require immediate attention. Combustion appliances must operate within strict ventilation standards to prevent carbon monoxide accumulation. Any uncertainty in this area warrants professional evaluation rather than experimentation.

Electrical irregularities, including tripped breakers that continue to reset or inconsistent power behavior, should also be handled by qualified service providers. Modern tankless systems integrate circuit boards and sensors that are not field-repairable without manufacturer-specific diagnostics.

When replacement parts are required, compatibility and calibration matter. Installing incorrect components can reduce efficiency, void warranties, or create long-term reliability issues. Professional service is often less costly than correcting improper installation later.

Repair Cost vs Replacement Cost

The age of the system usually determines whether a repair makes financial sense. Service calls for tankless water heaters typically include a diagnostic fee, which may range from moderate to substantial depending on region and complexity. Minor repairs involving sensors, ignition components, or descaling services are usually less expensive than major internal replacements.

Heat exchanger damage, however, changes the equation. The heat exchanger is the most critical and costly component of a tankless unit. When scale buildup or internal corrosion leads to exchanger failure, repair costs can approach a significant percentage of full replacement.

Age also matters. Most tankless systems are designed for long service life when maintained properly, but electronic boards, sensors, and valves may require replacement over time. Investing in repeated major repairs on an older unit may not be as economical as installing a new system with updated efficiency standards.

Replacement costs vary widely based on fuel type, venting configuration, and installation complexity. Gas units with new venting requirements or electrical upgrades can increase total installation expense beyond the base equipment price. A professional estimate provides clearer context than comparing appliance prices alone.

In most cases, the decision depends on system age, the severity of the failure, and how much service life remains after repair. Minor component service on a relatively new unit often makes sense. Major internal damage on an aging system may justify replacement instead.

Warning Signs You Should Not Ignore

Some symptoms should not be treated as routine inconvenience. While minor flow interruptions or isolated error codes can result from maintenance issues, certain warning signs suggest elevated risk.

A persistent gas odor near the unit warrants immediate attention. Even faint smells should not be dismissed. Gas appliances are designed to operate within sealed combustion systems, and irregular odors indicate that normal containment may be compromised.

Unusual exhaust smell, visible corrosion around venting components, or moisture accumulation inside sealed areas also require evaluation. These conditions can signal improper combustion or ventilation imbalance.

Water leaking from within the casing, especially if accompanied by fluctuating temperatures or system shutdown, may indicate internal component failure. Continued operation under these conditions increases long-term damage risk.

If the system repeatedly locks out after reset attempts, the shutdown mechanism is likely responding to a protective sensor. In these cases, professional diagnostics are safer than continued cycling.

Maintenance Practices That Reduce Future Repairs

Tankless systems are often described as low maintenance, but they still require routine care. Preventive care plays a significant role in long-term performance and repair frequency. Many failures that appear sudden are the result of gradual buildup or overlooked servicing.

Annual or biannual descaling is especially important in areas with hard water. Mineral accumulation inside the heat exchanger restricts heat transfer and increases internal strain. Over time, untreated scale contributes to overheating errors, reduced efficiency, and premature component wear.

Water quality also influences lifespan. Homes with high sediment content may require additional filtration to protect internal sensors and valves. Protecting flow components from debris reduces the likelihood of inconsistent activation or shutdown during use.

Environmental conditions surrounding the installation also matter. In unfinished basements especially, subtle floor movement or surface irregularities can influence equipment stability over time. Understanding how surface variation differs from structural movement helps prevent cosmetic corrections from masking deeper structural concerns.

Maintenance visits involve more than flushing alone. Technicians evaluate combustion performance, inspect venting integrity, and confirm that safety sensors are operating within specification. These checks help identify issues before they escalate into major repair events.

Consistent maintenance does not eliminate all risk of failure, but it reduces the probability of costly internal damage. In many cases, a properly maintained tankless unit delivers extended service life compared to neglected systems.

Frequently Asked Questions

Why does my tankless water heater suddenly go cold?

Sudden cold water often results from flow irregularities, ignition interruption, or protective shutdown triggered by an internal sensor. The system is designed to stop operation when conditions fall outside safe parameters.

How long do tankless water heaters usually last?

With consistent maintenance, tankless systems can operate for many years beyond the lifespan of traditional storage tank units. Longevity depends heavily on water quality, descaling frequency, and component wear over time.

Is it expensive to repair a tankless water heater?

Minor repairs such as sensor replacement or descaling service are typically less costly than major internal component failures. Heat exchanger damage or control board replacement can significantly increase repair expense.

Can I repair a tankless water heater myself?

Homeowners can safely perform visual checks, review error codes, and address basic maintenance issues. Internal component repair, gas adjustments, and electrical diagnostics should be handled by licensed professionals.

When should a tankless water heater be replaced instead of repaired?

Replacement becomes more practical when major internal components fail on an aging unit, when repeated repairs accumulate, or when updated efficiency standards make a newer system more cost-effective long term.

Note: Tankless water heaters operate using combustion or high-voltage electrical components. This article addresses general inspection and decision considerations. Internal gas adjustments, combustion diagnostics, and electrical repairs should be performed by licensed professionals.

Author & Editorial Review

- Author: Perla Irish — home systems and design writer covering residential infrastructure, surface behavior, and practical renovation decisions with a focus on safety-aware analysis.

- Editorial Review: This article was reviewed by the Living Bits & Things editorial team to ensure clarity, accuracy, and alignment with our internal quality and helpful-content standards. Learn more about our editorial review process.

Last updated: February 2026

Leave a Reply